Standard laboratory vacuum food lypholizer freeze dryer machnie

NBJ-10 series Freeze drying machine

NBJ-10 common experimental vacuum freeze dryer is widely used in medicine, pharmaceutical, biological research, chemical and food. The freeze-dried articles are easy to store for a long time, and can be restored to the state before lyophilization and maintain the original biochemical characteristics after adding water. NBJ-10 freeze dryer, suitable for laboratory use, meets the requirements of routine lyophilization in most laboratories.

Feature

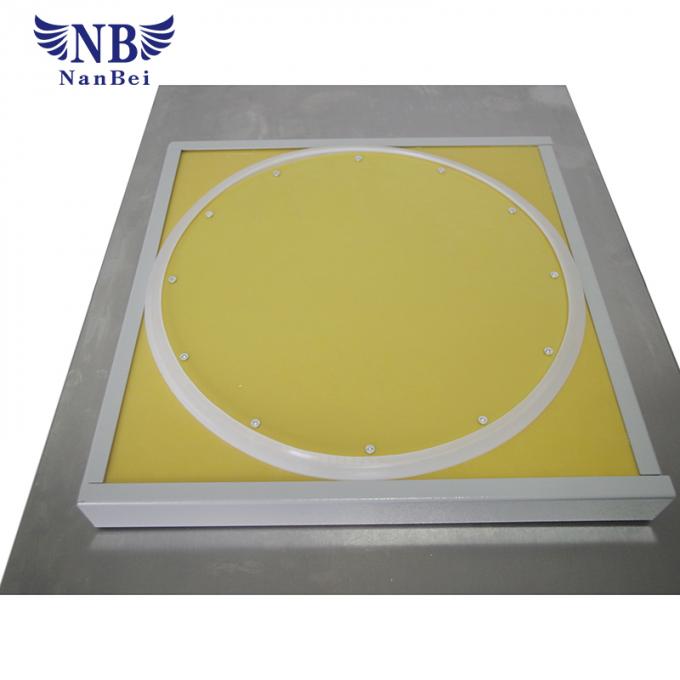

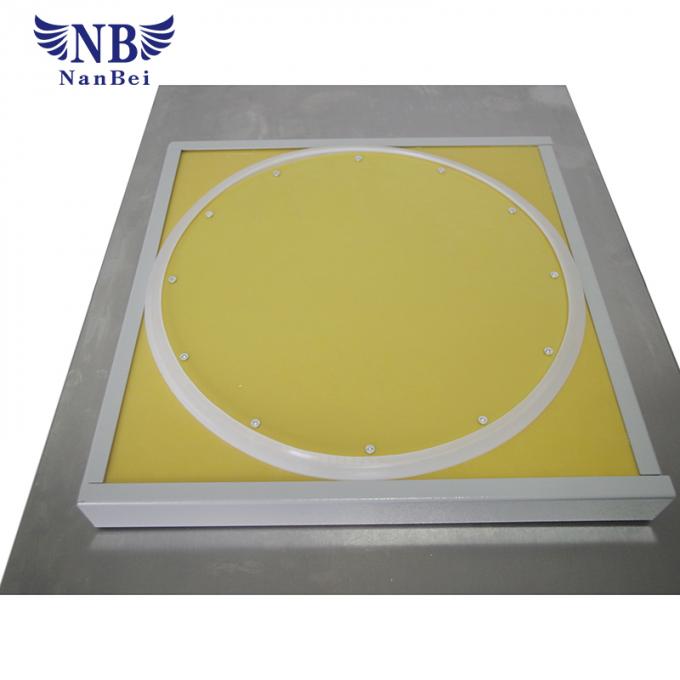

1. One-piece structure design, small size, no external flange, easy to use, no leakage.

2. All materials in contact with the product are made of inert materials to meet the requirements of GLP.

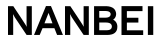

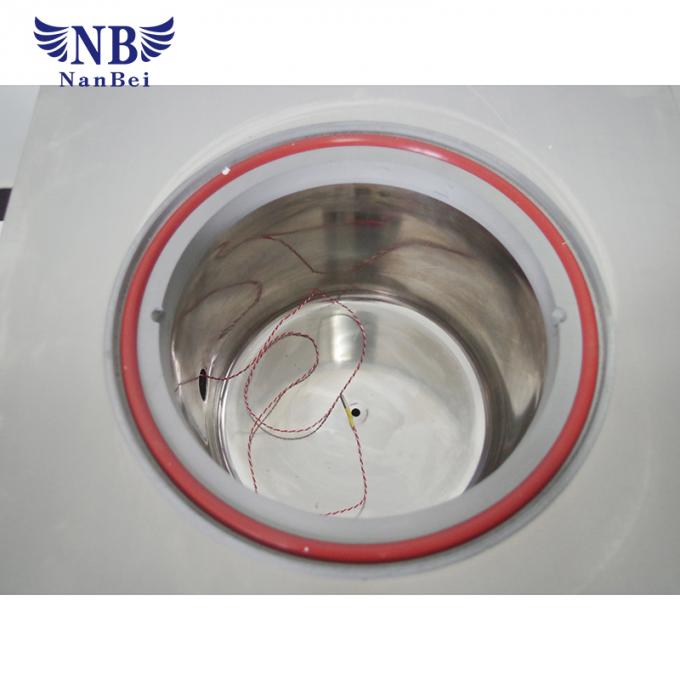

3. The cold trap and the operating table are made of stainless steel, which is corrosion-resistant and easy to clean.

4. All stainless steel inflatable (discharge) valves The company design, production, safety, anti-corrosion, no leakage.

5. The cold trap has a large opening, no inner coil, and sample pre-freezing function, no need for a low temperature refrigerator.

6. Specialized gas guiding technology, cold trap for uniform ice trapping and strong ice trapping ability.

7. Internationally renowned brand compressors, high efficiency, energy saving, long service life and low noise.

8. Well-known brand vacuum pump, pumping speed, to achieve a higher ultimate vacuum.

9. Vacuum pump protection function, can set the vacuum pump to start the cold trap temperature and protect the service life of the vacuum pump.

10. Professional design FD-LAB freeze dryer control system + SH-HPSC-I modular controller, with high reliability and stability.

11. Intelligent data recording system, real-time recording and display of cold trap temperature curve, sample temperature curve, vacuum curve, export data can be browsed by computer and printed.

Technical parameter

| Model | NBJ series vacuum freeze dryer |

| Type | Standard | Standard manifold | Top-press | Top-press manifold |

| Freeze drying area | 0.12m2 | 0.08m2 |

| Material plate size | Ф200mm | Ф180mm |

Your message must be between 3-3,000 characters!

Your message must be between 3-3,000 characters!

Please check your E-mail!

Please check your E-mail!

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters!

Please check your E-mail!

Please check your E-mail!