NANBEI Mini Vacuum Small Lab Scale Spray Dryer English Language PLC System

SP-1500 lab scale spray dryer is our latest type which is the result of our constant innovation in this field of laboratory scale spray drying systems through longtime cooperation between Witlab and Shanghai JiaoTong university.

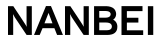

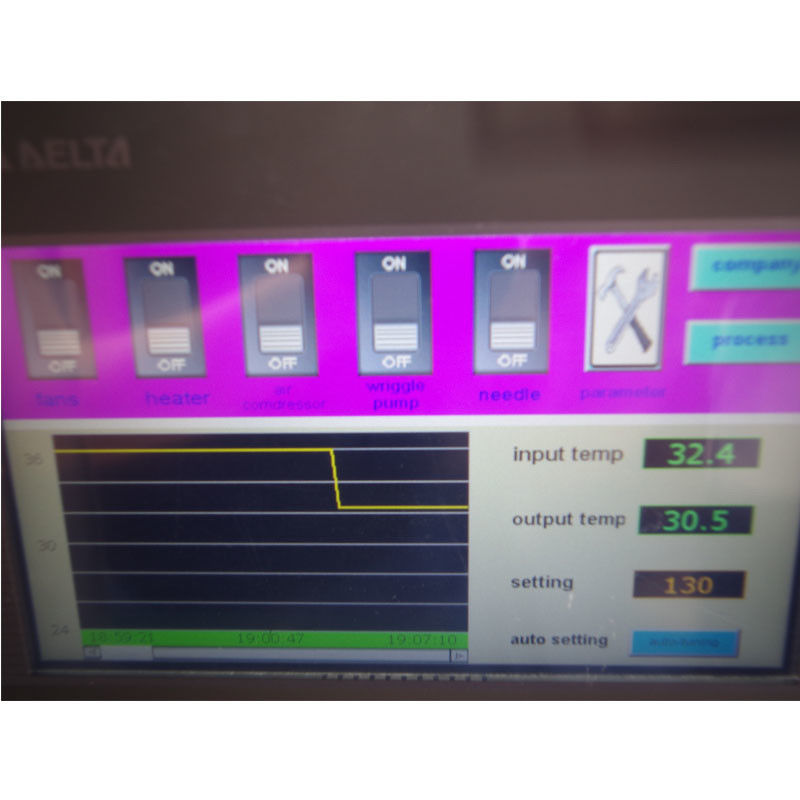

It assembles many of new design, for example, small shape for free moving, combining air compressor and electrical heater inside the cabinet, glass spray and cyclone separator for inspecting. All the data and function are controlled by PLC, English language.

APPLICATION:

various fields where the production of a free powder sample is required.

SP-1500 has successfully processed samples in the following areas: Beverage, Flavours and colourings, Milk and egg products, Plant and vegetable extracts, Pharmaceuticals, Synthetics Heat sensitive materials, Plastics polymers and resins, Perfumes, Blood, Ceramics and superconductors Biochemicals, Dyestuffs, Soaps and detergents, Foodstuffs, Adehesives, Oxides, Textiles, Bones, Teeth and tooth amalgam and many others.

TECH DATA:

| Model | SP-1500 |

| Max capacity | 1500-2000ml/h |

| Temperature range of Inlet air | 30ºC -280ºC |

| Temperature range of outlet air | 40ºC -120ºC |

| Precision of temperature | ± 1 ºC |

| Dryer time | 1.0-1.5 S |

| Speed of squirmy pump | 30-2000ml/h, |

| Consume of dryer air | 0-330m3 /h, max pressure: 686Pa |

| Consume of spray air | 0-4.2m3 /h, spray pressure: 2-5bar |

| Spray system | 2 liquid nozzles with standard 0.7mm jet

options of 0.5/1.0/1.5/2.0/2.5mm |

| Spray direction | downwards co-current |

| Power | 3.5KW 220V |

| Dimensions | 650×500×1550 ( mm ) L x W x H |

FEATURES:

1, Special for lab research, Min 20-30ml liquid to finish one test

2, All borosilicate glass for easy visual monitoring of process status.

3, Spray chamber, cyclone separator, receiving tank are all made of Borosilicate glass which can resist strong acid/alkali, high temperature. It can work in a no-pollution and stable environment.

4, Easy to clean and very simple to assemble and break down.

5, The air compressor is no oil and don't pollute compress air. The sound is low than 50db and following the GMP understands.

6, inlet/outlet temperature is accurate controlled by PID

7, The unit is self contained and supplied complete and ready for immediate operation.

8, Using screen touchable face display operation, control temperature, airflow volume, air pressure, pump speed and de-blocker frequency.

9, Product feeding with RS2559605 rotary pump, capacity is adjustable

10, Automatic de-blocking device prevents the nozzle from becoming blocked and variably controlled.

Your message must be between 3-3,000 characters!

Your message must be between 3-3,000 characters!

Please check your E-mail!

Please check your E-mail!

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters!

Please check your E-mail!

Please check your E-mail!